PB Weld S.R.L.

20 YEARS OF EXPERTISE IN THE WELDING INDUSTRY

Who are we?

PB WELD S.R.L. is a young, dynamic, and versatile company that operates as a specialized subcontracting partner in welding and processes such as anti-corrosion and wear-resistant coatings, surface and heat treatments, as well as non-destructive testing.

With over twenty years of experience gained by the owners in the OIL & GAS, NUCLEAR, GEOTHERMAL, and ENERGY sectors, the company is capable of managing special processes, strictly adhering to the technical requirements demanded by clients in these fields.

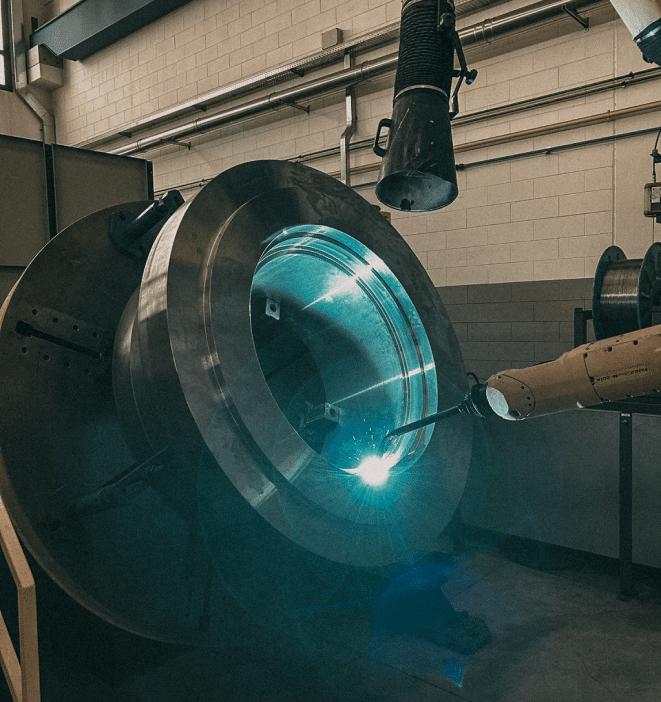

Our facility is equipped with cutting-edge robotic machinery and advanced welding technologies, allowing us to ensure high quality and cost optimization. Our team consists of highly qualified operators and welders with solid experience. We hold several welding certifications according to ASME and EN standards, and we provide support for the development of custom specifications for each project.

The welding processes we use include GMAW, GTAW, and SMAW, which allow us to work with a wide range of materials, from various types of carbon steel to stainless steel, duplex, superduplex, nickel-based alloys, bronze, titanium, and aluminum.

Quality and Certification

To confirm the quality and reliability of its services, PB WELD S.R.L. will obtain ISO 9001:2015 and ISO 3834-2 certifications by the end of 2024.

Currently, all the necessary quality procedures required for these certifications are in place and fully operational.

Regarding welding procedure qualifications, the company possesses a wide range of WPS/PQR and is available to develop new ones upon customer request.

Facilities and Equipment

PB WELD’s state-of-the-art, next-generation machinery allows us to achieve high levels of quality, safety, and productivity. These technologies enable the company to meet even the most demanding requirements, while also providing cost-competitive solutions.

The equipment includes:

2 robotic GMAW cells with a 10-ton capacity

2 robotic GMAW cells with a 3-ton capacity

1 automatic GMAW + GTAW hot and cold wire cell with a 700 kg capacity

2 manual welding stations

5 GMAW welding generators

2 GTAW welding generators

5 SMAW welding generators

1 10-ton overhead crane

1 250 kg jib crane

1 centralized extraction system

1 consumables storage facility

All equipment is housed in a total covered area of 750m².

Comprehensive Management

We set ourselves apart from other players in the industry.

Thanks to the experience of its team, PB WELD S.R.L. efficiently manages complex orders, optimizing the entire production process.

Whether following the ITP/QCP provided by clients or developing specific documents, all phases are carefully monitored and coordinated.

By managing the various stages of preparation, welding, finishing, and final inspection, we are able to oversee the entire production process, ensuring high standards of quality and meeting deadlines, while also optimizing costs.

Our services

With over 20 years of experience in the welding industry applied to the OIL & GAS, NUCLEAR, GEOTHERMAL, and ENERGY sectors, the company is capable of handling special processes with high technical requirements, addressing the most complex needs of clients in these fields.

Welding

We perform welding and weld overlays primarily for the oil & gas, energy, and nuclear sectors.

Machining, Grinding, Lapping

We manage turning, milling, grinding, and lapping processes in collaboration with various specialized workshops.

Revamping

We perform restoration work on mechanical components in general.

Non-destructive Testing

PB WELD S.R.L. is able to perform non-destructive testing at its own facility.

Consulting

PB WELD S.R.L. provides technical and commercial consulting related to the welding industry.

Contact us

Fill out the contact form, and an expert will get in touch with you as soon as possible.